Technology

Sparck Technologies’ commitment to customer experience

Spark Technologies is dedicated to its commitment to the customer experience. The CVP Impack automated packaging machine uses auto-Boxing Technology to construct, measure, label, and tape each single item or multi-item order in a seamless process. It makes packaging and fulfillment efficient and reliable. The CVP Impack saves you time and money with this tedious and time-consuming process.

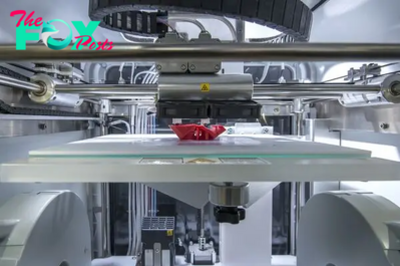

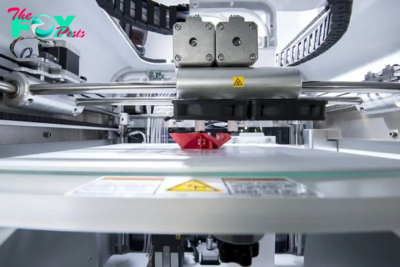

What Is the CVP Impack Automatic Packaging Machine?

The automated packaging CVP Impack of Sparck Technologies offers an easy way to package your orders. It increases the fulfillment process with automated packaging power. This machine works by integrating with your warehouse management system to meet growth demands. This is an ideal option for businesses that have a growing and expanding customer base.

The CVP Impack performs multiple tasks at once. It packs both hard and soft goods. It also scales and peaks with the growth of your business. You’ll improve customer service with faster processing and sustainable packaging methods.

How The CVP Impack Works

The CVP Impack works in seven simple steps. It requires one to three corrugate feeders that use agonistic fan-fold material for dynamic switching and replenishment. This saves your Business money on inventory and usage.

Next, is the choice between a single or dual induct station. It supports both high operation and machine productivity levels. The scanner will capture a 3D image of each item or group of items to determine the right box size. This demand box construction allows for a fit-to-size box that comes in your choice of sizes.

Each box is sealed with 2 or 3-inch tape that improves the return process and customer experience. It offers 100% security. The last step is the order weight verification which optimizes the rate of shopping with an in-line scale.

This assures accurate weight and measurements of each parcel. Last, the carrier complaint labels are made and applied to each package for accurate and timely delivery. Your customers will experience faster deliveries as a result. This improved process gives your customers more control by tracking the ordering and delivery process.

Advantages Of Automated Packaging

There are many advantages to using the CVP Impack automated packaging machine. Some of the biggest benefits are that it lowers label costs, utilizes the right-sized boxes, and increases the speed of packaging. It’ll automate your business to more profits. With a CVP Impack, you’ll save more time and money on traditional shipping standards.

It reduces 88% in packaging labor. You can eliminate between eight and 16 stations while reducing labor costs and increasing packaging processes. You’ll also experience a 50% reduction in shipping volume. It offers a wide variety of hard or soft single or multi-item orders in the right-sized box.

You can expect a 32% reduction in freight costs and a 38% reduction in material costs. It eliminates the need for larger-than-needed boxes that incur higher shipping costs. You’ll eliminate and minimize this void with the ideal fit-to-size box.

Reliable And Durable Packaging

The CVP Impack also offers durable and reliable packaging. Their mission is to help businesses deliver high-quality customer experience. Sparck offers a wide variety of options, including daily reporting, on-site services, part support, product training, remote support, and software maintenance. This company’s priority is to exceed the production and service needs.

As a result, you’ll get durable packaging options that fit the needs of your business. They’re made with high-quality and sustainable materials. You’ll also get access to direct customer service if you have any issues with the quality of production or packaging materials. Sparck’s customers are satisfied with the service options, support, and CVDP uptime since it exceeds their productivity goals.

About Spark Technologies

Sparck Technologies is based in Drachten, the Netherlands. They help some of the world’s largest industrial and retail brands. They became known for their innovative automated packaging solutions, engineering expertise, reliability, durability, and performance that can’t be met.

The brand made its start in 1924 and have a long history with automated packaging solutions. For example, they built the first automatic clog machine in the 1920s. They can help you streamline your parcel-packing process with automation solutions. Visit Spark Technologies for more information about the CVP Impack and its automated packaging solutions.

-

Technology9h ago

Technology9h agoChipmaker Intel falls as AI competition hurts forecast

-

Technology13h ago

Technology13h agoEric Schmidt and Yoshua Bengio Debate How Much A.I. Should Scare Us

-

Technology16h ago

Technology16h agoAlphabet, Microsoft earnings show hefty AI bets are driving growth

-

Technology16h ago

Technology16h agoArgentine scientists find speedy 90-million-year-old herbivore dinosaur

-

Technology21h ago

Technology21h agoUnder the influence and under arrest − what happens if you’re drunk in the interrogation room?

-

Technology21h ago

Technology21h agoCybersecurity researchers spotlight a new ransomware threat – be careful where you upload files

-

Technology1d ago

Technology1d agoWhat a TikTok Ban in the U.S. Could Mean for You

-

Technology1d ago

Technology1d agoWhat Is Artificial Intelligence Consciousness And How Far Away Is It?